Variable Frequency Drives (VFDs) have become an essential component in modern industrial and agricultural systems, offering precise motor control, energy efficiency, and extended equipment life. However, despite their many benefits, users often encounter certain concerns when integrating VFDs into their systems. Among them, the most common issue is harmonic distortion and electrical interference, which can lead to system instability, overheating, or unexpected downtime if not addressed properly.

Why Are Harmonics a Problem in VFD Usage?

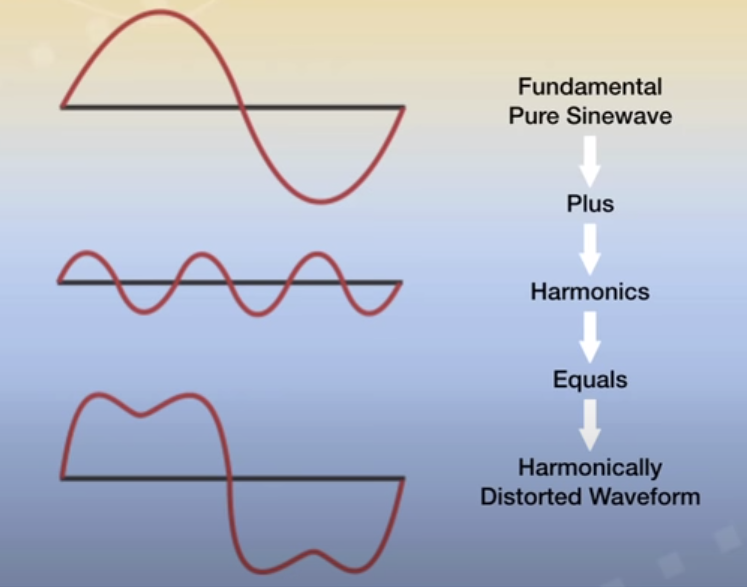

Harmonics, caused by the switching nature of VFDs, are distorted voltage or current waveforms that can interfere with other equipment on the same power network. Since VFDs operate by converting AC power to DC and back to variable-frequency AC, they introduce high-frequency noise into the system. This can result in:

- Excessive heating of motors and transformers

- Malfunctioning of nearby sensitive equipment

- Poor power factor and increased utility charges

- Unexplained tripping of circuit protection devices

In facilities with multiple VFDs or sensitive automation components, this issue becomes even more critical. Without mitigation strategies such as harmonic filters or proper grounding, system reliability can be compromised.

How Can Electrical Interference Affect System Performance?

Electrical interference, or electromagnetic interference (EMI), is another widespread concern associated with Variable Frequency Drives. EMI can disrupt communication lines, PLCs (Programmable Logic Controllers), and even sensors. This happens when the VFD’s high-frequency switching creates unwanted signals that couple into control circuits or communication cables. Some key symptoms include:

- Erratic sensor readings

- PLC communication errors

- False alarms or unexpected system behavior

Such problems are especially common in industrial plants or pumping systems with long cable runs or poorly shielded components. To counter this, proper cable shielding, grounding, and VFDs with built-in EMI filters are highly recommended.

Are Variable Frequency Drives Difficult to Maintain or Troubleshoot?

Another concern users face is the perceived complexity in Variable Frequency Drive setup and maintenance. VFDs offer numerous configuration parameters, and without adequate understanding, users might:

- Select incorrect voltage or frequency limits

- Misconfigure ramp-up/down settings

- Fail to program motor protection features properly

These missteps can result in overloading, reduced efficiency, or even motor damage. Fortunately, modern VFDs—such as those from LCGK—come with intuitive displays, pre-programmed templates, and detailed manuals that simplify the setup process. Training and technical support also play a major role in easing this concern.

Do Variable Frequency Drives Cause Issues With Motor Insulation or Cable Stress?

Yes, especially in older motor systems. Variable Frequency Drives generate high-voltage spikes and fast rise times, which can stress motor insulation, particularly over long cable distances. This is known as voltage reflection. Over time, it can degrade the motor’s life expectancy. Common preventive strategies include:

- Using inverter-rated motors

- Installing dv/dt filters or sine wave filters

- Selecting proper cable types with low impedance

These practices are increasingly standard, especially in VFD applications involving submersible pumps, compressors, and agricultural irrigation.

How Can These Concerns Be Minimized Effectively?

While these issues are valid, they are also entirely manageable with proper system design and product selection. A few key tips include:

- Conducting a harmonic analysis before large-scale installation

- Choosing VFDs with built-in protective features

- Implementing EMI shielding and proper cable routing

- Ensuring motor compatibility with the selected VFD

- Consulting experienced technical support teams during commissioning

Modern VFD solutions like those from LCGK are engineered with these concerns in mind, offering integrated filters, smart diagnostics, and user-friendly interfaces to minimize potential risks from the start.

Conclusion

While harmonic distortion and electrical interference remain the most common concerns with using Variable Frequency Drives, they can be effectively addressed through thoughtful planning, proper component selection, and high-quality VFD products. By understanding these challenges and implementing proven solutions, businesses can unlock the full potential of variable frequency drives—boosting energy savings, system longevity, and operational control.

At LCGK, we specialize in delivering reliable and user-friendly VFD solutions tailored for diverse applications including solar pumping, industrial automation, and irrigation systems. Our products are engineered to minimize harmonic impact, reduce EMI, and simplify setup—ensuring your investment is both efficient and long-lasting.