When it comes to selecting the right technology for motor control, understanding the differences between a solar pump inverter and a VFD (variable frequency drive) is crucial. Although both systems regulate motor speed, their energy sources, applications, and operating principles are quite distinct. In this article, we will explore how each device works, their unique benefits, and guide you toward choosing the best solution for your specific needs.

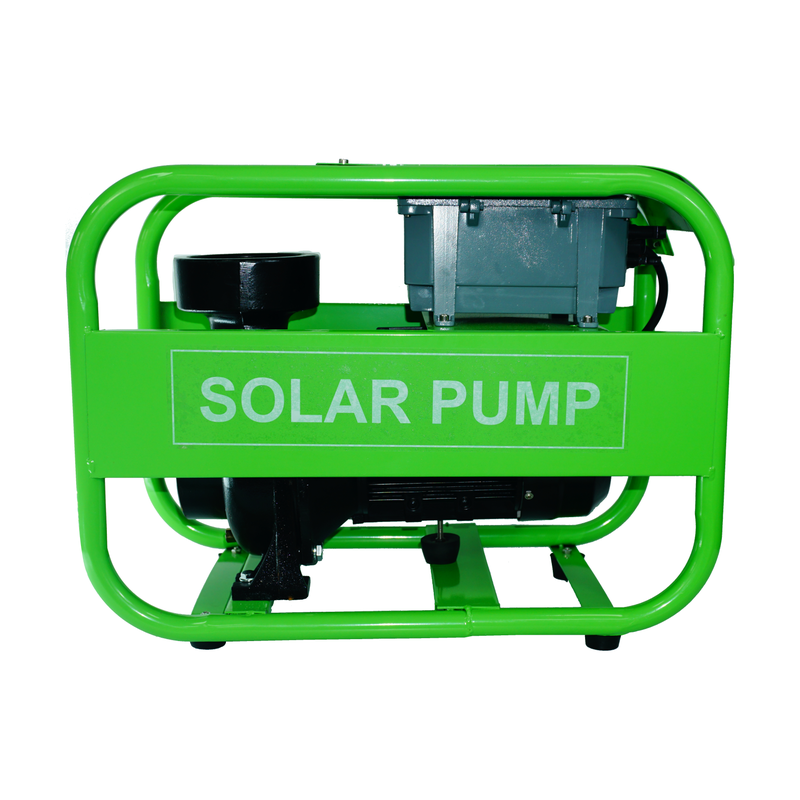

What is a Solar Pump Inverter?

A solar pump inverter is a specialized device that plays a crucial role in solar-powered water pumping systems. It is responsible for converting the direct current (DC) generated by solar panels into alternating current (AC), which is necessary to drive most water pump motors. Without this conversion, solar panels alone would not be able to operate standard AC pumps effectively.

Beyond simple current conversion, modern solar pump inverters are equipped with advanced technologies like Maximum Power Point Tracking (MPPT). MPPT algorithms constantly monitor solar panel output and dynamically adjust operating parameters to extract the maximum possible power under varying sunlight conditions, such as cloud cover, morning light, or peak sun hours. This ensures that even during less-than-ideal weather, the system continues to deliver reliable water flow.

Many solar pump inverters also incorporate intelligent protection features, including dry-run protection (preventing pump damage if the water source runs dry), overvoltage safeguards, overheating alarms, and automatic shutdown in extreme conditions. These functions significantly extend the lifespan of both the inverter and the connected water pump.

Typical Applications

Solar pump inverters are predominantly used in locations where connecting to the electrical grid is impractical or cost-prohibitive. They are essential for:

Agricultural irrigation in remote fields, ensuring crops receive timely watering without manual intervention.

Livestock watering systems on ranches, where animals require consistent access to fresh water.

Rural community water supply projects, particularly in developing regions with minimal infrastructure.

Off-grid household or industrial water pumping, helping reduce reliance on costly diesel generators.

Key Features

Solar energy utilization: Eliminates electricity bills and reduces carbon footprint.

Automatic start/stop based on sunlight intensity: No need for manual intervention to operate the system.

Protection against dry running, overvoltage, and overload: Safeguards equipment under harsh conditions.

Energy independence and reduced operational costs: Once installed, the system offers minimal running expenses, ideal for long-term sustainability.

By harnessing solar power effectively, these inverters enable continuous water supply solutions even in isolated, sun-rich environments, making them an essential component for sustainable development and modern agriculture.

What is a VFD (Variable Frequency Drive)?

A Variable Frequency Drive (VFD) is an electronic device that precisely controls the speed, torque, and direction of an AC motor by adjusting the frequency and voltage of the power supplied to it. By manipulating these two key parameters, a VFD enables motors to operate exactly at the speed needed for a specific task, instead of running at a constant full speed regardless of demand. This not only optimizes performance but also leads to significant energy savings.

Internally, a VFD typically consists of three main sections: a rectifier, an intermediate DC bus, and an inverter. The rectifier first converts incoming AC power into DC. Then, through the inverter section, the DC is converted back to a synthesized AC output with variable frequency and voltage. This synthetic AC waveform is what ultimately controls motor speed in a finely tuned manner.

In addition to basic speed control, modern VFDs often feature advanced functionalities like dynamic braking, programmable acceleration/deceleration profiles, and communication interfaces (such as Modbus or Ethernet) for integration into broader automation systems. Many VFDs also incorporate energy monitoring capabilities, helping facilities track and optimize energy usage over time.

Typical Applications

VFDs are extensively deployed in commercial and industrial environments where precision motor control is required, such as:

Conveyor belts in manufacturing plants, ensuring products move at the right pace through production lines.

HVAC systems in commercial buildings, enabling precise airflow and temperature control.

Industrial pumps, compressors, and fans, where motor speed must adjust dynamically based on process needs.

Building automation systems, enhancing energy management and operational efficiency.

Key Features

Precise control over motor speed and torque: Tailors performance to the exact needs of the application.

Energy savings through optimized motor operation: Reduces electricity consumption during low-demand periods.

Smooth start and stop to reduce mechanical stress: Extends the lifespan of motors and associated machinery.

Improved equipment lifespan and reduced maintenance costs: Leads to long-term operational savings.

In industries that require flexibility, precision, and efficiency, VFDs provide an invaluable advantage by combining operational control with significant cost reductions.

Key Differences Between Solar Pump Inverter and VFD

While solar pump inverters and VFDs may seem similar at first glance—both controlling motor speed—their design purposes, operating environments, and performance goals are quite different. Understanding these distinctions is essential when deciding which system best suits a specific application.

At their core, the primary difference lies in their energy source and targeted functionality. Solar pump inverters are engineered specifically for use with solar photovoltaic (PV) systems. They are optimized to handle the fluctuations of solar energy, adapting pump operation based on sunlight availability, and maximizing energy conversion even under partial shading or cloudy conditions. Their integrated MPPT algorithms ensure that every watt of solar energy is effectively utilized to drive water pumps, crucial for regions where power reliability is a concern.

On the other hand, a VFD operates within a grid-connected environment. It controls motor speed based on system demand, not on the variability of power availability. Its primary role is to deliver precise, responsive control in stable electricity environments, thereby enhancing process efficiency, reducing mechanical wear, and cutting down on energy waste.

Another notable difference is in the system cost and deployment. Solar pump inverters generally come at a higher initial investment due to their specialized design for solar integration, including advanced electronics for MPPT and protective features. However, they provide long-term savings by eliminating electricity bills. VFDs, being standardized for conventional AC power, are typically less expensive upfront and are widely available across industrial markets.

Here’s a summarized comparison to clearly highlight these differences:

| Feature | Solar Pump Inverter | VFD (Variable Frequency Drive) |

| Power Source | Solar panels (DC) | Grid electricity (AC) |

| Primary Use | Off-grid water pumping | Industrial and commercial motor control |

| Efficiency Focus | MPPT for maximum solar usage | Speed adjustment for load matching |

| Cost | Higher, due to solar optimization | Generally more affordable |

| Energy Dependency | Independent of grid power | Dependent on stable grid supply |

Each technology brings unique value depending on the scenario: solar pump inverters are indispensable where grid access is limited, while VFDs are the go-to choice for maximizing motor performance in modern industrial setups.

How Do Solar Pump Inverters and VFDs Improve Efficiency?

Both solar pump inverters and variable frequency drives (VFDs) significantly enhance system efficiency, but they do so using very different strategies aligned with their distinct energy environments and operational goals.

Solar Pump Inverters

Solar pump inverters maximize efficiency by making the most of the fluctuating power output from solar panels. Thanks to built-in Maximum Power Point Tracking (MPPT) technology, they continuously adjust operating parameters to capture the optimal energy output even when sunlight intensity varies throughout the day. This real-time optimization ensures that the connected water pumps operate reliably from sunrise to sunset, delivering consistent water output with minimal energy wastage.

Moreover, many modern solar pump inverters feature adaptive pumping algorithms. These smart algorithms dynamically adjust the pump’s speed based on available solar energy—slowing down during cloudy periods and ramping up during peak sunlight. This protects the pump from operating under unfavorable conditions, minimizes downtime, and extends equipment lifespan.

Another key advantage is the independence from the grid. By running purely on renewable energy, solar pump systems reduce operational costs dramatically and eliminate the environmental impact associated with fossil-fuel-based electricity generation.

VFDs

VFDs improve efficiency in a different but equally important way. Instead of simply turning motors on and off at full speed, VFDs allow motors to operate precisely at the speed required for a given load. For example, in a pumping system, if only 50% flow is needed, a VFD can slow the pump motor accordingly, significantly reducing energy consumption compared to running at full speed with throttling valves.

This load-matching capability results in substantial energy savings, especially in systems where the load varies throughout the day. Additionally, smooth start and stop functions built into VFDs reduce the mechanical stress on pumps, fans, and conveyors, which not only saves energy but also cuts down on wear and tear, extending the service life of the machinery.

Furthermore, VFDs often support energy monitoring and diagnostics, allowing facility managers to track power consumption patterns and identify opportunities for further energy optimization across their operations.

In summary, whether through renewable energy optimization or intelligent load management, both solar pump inverters and VFDs play pivotal roles in boosting efficiency, reducing costs, and promoting more sustainable operation models.

When Should You Choose a Solar Pump Inverter vs. a VFD?

Choosing between a solar pump inverter and a VFD ultimately depends on several critical factors, including your power availability, application environment, budget, and long-term operational goals. Both technologies offer distinct advantages, but they are best suited for different scenarios.

Choose a Solar Pump Inverter If:

You are in a remote or off-grid location: If your installation site is far from the electrical grid or faces frequent power outages, a solar pump inverter is the ideal choice. It enables fully independent water pumping systems powered purely by solar energy.

You have abundant sunlight: Areas with strong, consistent sunlight can maximize the effectiveness of solar pump inverters, ensuring continuous operation throughout most of the year.

You want to minimize operational costs: Although the initial setup of a solar pumping system might be higher, the absence of electricity bills, minimal maintenance requirements, and government incentives for renewable energy adoption can lead to significant long-term savings.

You seek sustainable solutions: For farms, ranches, eco-resorts, or rural water supply projects focused on sustainability, solar pump inverters contribute toward achieving environmental goals by leveraging clean, renewable energy.

Choose a VFD If:

You have reliable access to grid electricity: In facilities with stable and cost-effective grid power, VFDs provide an excellent way to optimize energy use and control motor performance without needing to invest in solar infrastructure.

Your operation demands precision control: Applications that require variable motor speeds, frequent starting and stopping, or specific torque requirements—such as manufacturing production lines, HVAC systems, or automated pumping stations—benefit greatly from the fine-tuned control capabilities of VFDs.

You want to extend equipment lifespan: By enabling soft starts, gentle stops, and load-based operation, VFDs help prevent mechanical stress and reduce maintenance frequency, resulting in longer service life for pumps, compressors, and other rotating machinery.

You aim for quick payback through energy savings: Especially in variable-load applications, the energy savings achieved by using a VFD can quickly offset the initial cost of installation, delivering a fast return on investment.

In some cases, a hybrid approach may even be feasible, where VFDs are used alongside backup solar systems, depending on the complexity and needs of the operation.

By carefully analyzing the specific environmental, technical, and financial factors involved, users can confidently select the technology that aligns best with their operational objectives and site conditions.

Conclusion

Selecting the right solution between a solar pump inverter and a variable frequency drive (VFD) comes down to understanding your operational context, energy availability, and long-term efficiency goals. Each technology is purpose-built to excel in specific environments, and choosing the appropriate one can dramatically enhance system performance, energy savings, and equipment longevity.

If your project involves off-grid water pumping, particularly in remote agricultural fields, rural communities, or areas with unstable grid access, a solar pump inverter offers an unmatched advantage. By tapping into abundant solar energy and operating independently of the grid, solar pump inverters ensure a reliable, cost-effective, and environmentally sustainable water supply. Features like MPPT optimization, intelligent protection systems, and automatic operation make solar pump inverters a powerful solution for modern water management.

Conversely, if you operate within a grid-connected facility—such as a factory, office building, or urban infrastructure—a VFD is often the better investment. Its ability to dynamically control motor speeds based on real-time demand not only cuts energy consumption but also improves equipment performance, reduces maintenance costs, and extends operational lifespan. Whether controlling pumps, fans, or conveyors, VFDs provide critical flexibility and operational efficiency for industrial and commercial processes.

Both technologies represent significant strides toward smarter, more sustainable motor control systems. By carefully evaluating your specific project needs—considering factors such as site location, energy resources, operational demands, and budget—you can make a choice that supports both immediate performance and long-term resilience.

If you’re looking for a trusted partner to help you implement a reliable solar pump solution, LCGK offers a range of advanced solar pump inverters designed to deliver outstanding efficiency, robust protection, and easy integration even under challenging environmental conditions. Explore LCGK’s innovative solutions to take your solar water pumping projects to the next level with confidence.