As agriculture and water management systems move toward greater sustainability and independence from the electrical grid, solar pump inverters have emerged as a cornerstone technology. These intelligent devices bridge the gap between solar energy and motor-driven water pumps, delivering consistent water flow with maximum energy efficiency. Whether you’re running a small irrigation system or a large-scale deep well setup, selecting the right solar pump inverter is critical to system stability, longevity, and performance.

What Is a Solar Pump Inverter and How Does It Work in Irrigation Systems?

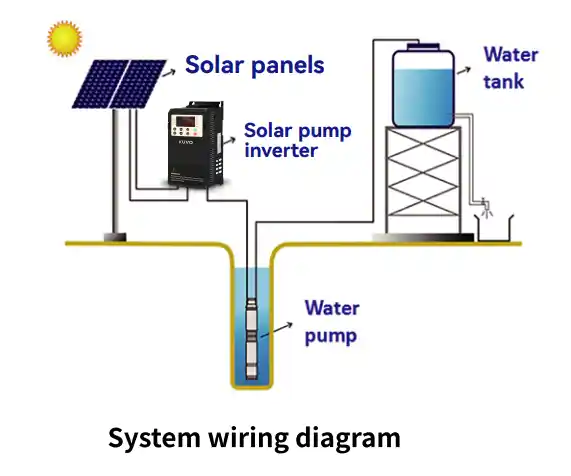

A solar pump inverter is a specialized device designed to convert the direct current (DC) from solar panels into alternating current (AC) that drives water pumps. Unlike conventional inverters, it is engineered with intelligent control functions to manage both power conversion and water flow requirements. This makes it an ideal choice for irrigation systems, agricultural fields, and remote water supply solutions.

Core Working Principle

The inverter continuously adjusts the pump speed based on the available solar energy, ensuring maximum power utilization without overloading the pump. When solar radiation is high, the pump operates at its peak efficiency, while during cloudy conditions, the inverter reduces pump speed to match the power output. This dynamic adjustment not only guarantees reliable water delivery but also reduces mechanical wear and energy waste.

Advantages Over Traditional Systems

A solar pump inverter eliminates the need for grid power or diesel generators, reducing operational costs and maintenance. It integrates functions like Maximum Power Point Tracking (MPPT) to optimize energy conversion from solar panels, ensuring stable water flow throughout the day. For example, LCGK VFD’s KV100A-7.5-15KW solar pump inverter offers high dynamic response capability, ideal for continuous irrigation needs.

Why Is MPPT and Vector Control Critical for Solar Pump Inverter Performance?

Solar pump inverters are not just power converters—they are intelligent controllers that adapt to environmental and operational conditions in real time. Among the core technologies that enable this adaptability are Maximum Power Point Tracking (MPPT) and high-performance vector control. These two features are essential for achieving both energy efficiency and stable water output in solar-powered irrigation systems.

What Is MPPT and Why Does It Matter?

MPPT (Maximum Power Point Tracking) is a critical algorithm built into modern solar pump inverters. It continuously monitors the voltage and current output from the solar panels to identify the “maximum power point”—the optimal operating condition where solar panels produce the highest possible power.

Without MPPT, fluctuations in sunlight—caused by clouds, dust, or time of day—can result in significant energy losses. With MPPT, the inverter dynamically adjusts to ensure that even under variable light conditions, your system captures as much solar energy as possible.

In agricultural environments where sunlight availability changes throughout the day, MPPT ensures consistent pump performance and avoids dry runs or overflows.

Example: LCGK’s KV90PV-15-18KW solar pump inverter features an advanced MPPT module that maintains high efficiency even during partial shading, ensuring reliable irrigation during all daylight hours.

The Role of Vector Control in Water Pump Stability

While MPPT manages solar input, vector control governs the motor output. It allows the inverter to precisely regulate the torque and speed of the water pump motor—even when no speed sensor is installed. This sensor-less vector control offers high starting torque, smoother pump acceleration, and fine-grained speed adjustments depending on the irrigation requirement.

High-performance vector control also enables closed-loop operation in some models, which ensures exact feedback control for constant pressure applications, such as in drip irrigation or livestock watering.

For instance, LCGK VFD’s KV100A-18.5-22KW and KV100A-0.75-2.2KW inverters both support sensor-free and closed-loop vector control, making them suitable for a range of irrigation setups—from small rural gardens to large-scale farms.

Benefits of Combining MPPT and Vector Control

When combined, MPPT and vector control allow the solar pump inverter to:

Harvest the maximum available solar energy in real time.

Convert this energy into the exact torque and speed required by the water pump.

Avoid energy waste, dry running, and equipment damage.

Support applications where pressure and flow rate must remain constant.

This synergy between solar input optimization and motor output regulation is what sets high-quality inverters apart from basic systems, delivering reliable water access with minimal supervision.

How to Select the Right Solar Pump Inverter for Your Water System?

Choosing the appropriate solar pump inverter is essential for the efficiency, longevity, and reliability of your entire water supply system. A mismatch in inverter capacity, functionality, or control features can lead to energy waste, motor damage, or inconsistent water delivery. To make an informed decision, several key factors must be considered—each tied closely to the specific requirements of your water system.

1. What Is the Power Rating of Your Water Pump?

Start by identifying the rated power (in kW) of your pump motor. The inverter must match or slightly exceed this rating to ensure reliable operation under all conditions, especially during startup, when the motor draws higher current.

For small-scale systems such as garden irrigation or single livestock tanks, models like KV100A-0.75-2.2KW or KV90PV-0.75-2.25KW offer a compact, cost-effective solution.

For mid-sized agricultural setups, the KV90PV-4KW-5.5KW and KV100A-4-5.5KW provide enough power with integrated MPPT and vector control.

For large-scale field irrigation, options such as KV90PV-15-18KW or KV100A-18.5-22KW can drive high-flow submersible or centrifugal pumps reliably.

Always allow a 10–15% headroom in inverter capacity to account for heat, startup current, and fluctuations in solar input.

2. What Type of Water Source and Pump Are You Using?

Different water systems require different inverter control strategies. Submersible pumps, surface pumps, and booster systems each place unique demands on the inverter:

Submersible deep-well pumps need high torque at startup and stable operation at varying depths. Choose inverters with vector control and dry-run protection, such as LCGK’s KV100A-7.5-15KW.

Surface pumps or shallow wells benefit from quick-start and energy-efficient operation—models with MPPT but lower output may suffice.

Boosting systems (like drip or sprinkler irrigation) need constant pressure, making closed-loop control support a valuable feature.

3. Does Your Site Have Fluctuating Solar Conditions?

If your installation is in an area with variable sunlight, an inverter with robust MPPT and wide input voltage tolerance is essential. This ensures operation even during cloudy periods or early/late sunlight hours.

LCGK’s KV90PV series is engineered for such conditions, with intelligent MPPT tracking and adaptive power regulation across all major power levels—from KV90PV-7.5KW-11KW to KV90PV-22-30KW.

4. Do You Need Smart Features or Protections?

Beyond basic conversion, advanced solar pump inverters offer features like:

Automatic start/stop based on sunlight levels

Dry-run protection to avoid pump damage

Over-voltage and over-temperature safeguards

Remote monitoring or external controller integration

These features reduce maintenance and prevent system failures, especially in remote locations. Models like KV100A-18.5-22KW are often used where intelligent fault handling is critical.

By carefully evaluating these parameters—power rating, pump type, site conditions, and smart controls—you can choose the inverter that best fits your water system’s needs, ensuring stable and energy-efficient performance year-round.

What Are the Common Power Ranges and Applications of Solar Pump Inverters?

Solar pump inverters come in a wide range of power ratings to accommodate diverse water system requirements—from low-power garden setups to high-capacity agricultural and industrial pumping systems. Understanding how different power ranges align with specific applications will help ensure optimal performance, longevity, and return on investment.

1. Low Power Range (0.75KW – 2.25KW): Precision for Small-Scale Systems

Low-power inverters like the KV100A-0.75-2.2KW and KV90PV-0.75-2.25KW are ideal for small water pumping tasks. These models are compact, efficient, and cost-effective, making them perfect for:

Household gardens or landscaping irrigation

Small livestock watering stations

Greenhouses or seedling operations with limited water needs

Despite their small size, these inverters still feature MPPT and sensor-free vector control, ensuring stable output even when sunlight conditions change.

2. Medium Power Range (4KW – 7.5KW – 11KW): Versatility for Mid-Scale Irrigation

Mid-range inverters, such as the KV90PV-4KW-5.5KW and KV90PV-7.5KW-11KW, provide higher capacity and more robust control features. These units are well-suited for:

Open-field drip or sprinkler irrigation systems

Mid-size farms or cooperatives

Shallow or medium-depth well systems requiring moderate water flow

These inverters often support additional functions like soft start, overload protection, and auto-resume after fault, ensuring consistent performance and reduced system downtime.

3. High Power Range (15KW – 30KW): Heavy-Duty Performance for Agricultural and Industrial Use

For demanding applications, such as deep-well irrigation or industrial water delivery, high-capacity inverters like KV90PV-15-18KW, KV100A-18.5-22KW, and KV90PV-22-30KW are designed to handle:

Multi-zone irrigation systems on large agricultural plots

Pumping water over long distances or to elevated storage tanks

Industrial washdown or cleaning systems requiring high pressure and flow

Rural water supply projects for entire communities

These models are built with enhanced heat dissipation, real-time monitoring, and fully programmable logic, making them highly adaptable and durable in the most challenging environments.

4. Application Scalability with Modular Inverter Use

For systems that grow over time, modular inverter design offers flexibility. Start with a KV100A-4-5.5KW for a smaller system, and scale up by integrating additional units or upgrading to KV100A-7.5-15KW as water demands increase. This makes them future-proof and ideal for operations planning long-term expansion.

By aligning inverter power ratings with your specific application needs, you avoid overinvestment while ensuring the pump operates efficiently throughout the day. LCGK’s wide range of solar pump inverter models covers every use case—from micro-systems to industrial-grade water solutions—ensuring precision, performance, and peace of mind.

How Can You Maximize Efficiency and Lifespan in Solar Pump Inverter Systems?

Investing in a solar pump inverter is a smart long-term decision, but the real value comes from keeping the system efficient, reliable, and low-maintenance over many years. To do that, you need more than just a good product—you need a system that is properly installed, monitored, and maintained.

Below are essential strategies to help you maximize both performance and lifespan of your solar pump inverter system.

1. Ensure Proper Sizing and Matching of Components

Efficiency begins with compatibility. Your solar panels, inverter, and pump motor must be properly sized and matched:

Inverter input voltage range should align with the solar array output. For instance, if you choose KV90PV-15-18KW, make sure your PV configuration meets the inverter’s recommended voltage range for optimal MPPT performance.

Inverter output capacity must slightly exceed the rated power of the pump motor, especially in large systems like those using KV90PV-22-30KW.

Cable lengths and wire gauges should be optimized to minimize voltage drop between panels, inverter, and pump.

A mismatch in any of these elements can result in efficiency loss, system faults, or even permanent equipment damage.

2. Implement Smart Monitoring and Control Features

Modern inverters like LCGK’s KV100A and KV90PV series support smart features such as:

Real-time fault alerts

Remote monitoring

Automatic restart after voltage drops

Daily runtime logs

Use these tools to detect anomalies early, reduce manual inspections, and ensure your system is always operating at peak conditions. For instance, if your system shuts down due to dry-run protection, a remote alert can save you a site visit.

3. Protect the Inverter from Environmental Hazards

Although solar inverters are robust, environmental exposure can degrade them over time:

Install the inverter in a shaded, ventilated area to reduce heat accumulation.

Use weatherproof enclosures if the system is outdoors and unprotected.

Ensure dust filters are periodically cleaned, especially in agricultural or desert regions.

Models like the KV100A-18.5-22KW are designed with industrial-grade enclosures and cooling systems, but good installation practices remain crucial.

4. Schedule Preventive Maintenance

While solar pump inverters are largely autonomous, periodic checks can help you catch issues early:

Inspect solar panels for dirt, debris, or shading.

Verify inverter logs for voltage irregularities.

Monitor pump pressure and water flow for consistency.

Check cables and terminals for signs of corrosion or loosening.

Routine maintenance not only extends the life of your system but also ensures consistent irrigation output and reduces unexpected downtime.

5. Upgrade Firmware and Use Original Components

For systems operating year-round, occasional firmware updates may enhance performance or add new features. Also, always use original manufacturer parts (e.g., filters, connectors, and cables) when replacements are needed to maintain system integrity.

By following these strategies, you not only protect your solar pump investment but also ensure reliable water access, energy savings, and minimal maintenance over time. LCGK’s range of inverters, including the KV100A and KV90PV series, is engineered for high-efficiency operation and built-in protections—making them an ideal long-term partner in your irrigation or water management system.

Conclusion

A well-chosen and properly managed solar pump inverter does more than power a pump—it ensures continuous, cost-effective, and low-maintenance water delivery from renewable energy. With features like MPPT, vector control, and fault protection, inverters such as the LCGK KV100A and KV90PV series are engineered to meet the complex demands of modern irrigation and water supply systems. By understanding the technology, selecting the right model, and maintaining your setup with care, you unlock the full potential of solar-driven water pumping—economically and sustainably.