In today’s search for reliable and sustainable water solutions, the solar pump inverter has become a cornerstone technology for modern pumping systems. Traditional pumps powered by grid electricity or diesel generators often face challenges such as high energy costs, unstable supply, and increased maintenance demands. By integrating advanced inverter control with solar energy, a solar pump inverter ensures that water pumps operate efficiently, adapt to changing load conditions, and deliver consistent performance across diverse environments.

This innovation not only reduces operational costs but also extends the service life of equipment, making it a preferred solution in irrigation, livestock watering, community water supply, and industrial operations. As industries and organizations continue to prioritize both efficiency and sustainability, the solar pump inverter provides a practical and future-ready path to dependable water management.

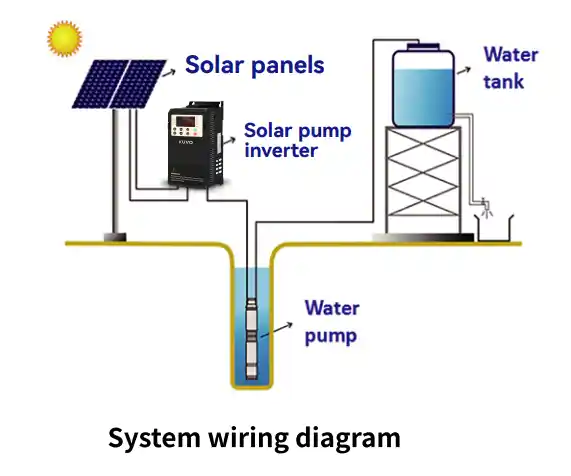

What Is a Solar Pump Inverter and How Does It Work?

Understanding the Core Function

A solar pump inverter is a device that converts the direct current (DC) generated by solar panels into alternating current (AC) to drive water pumps. Unlike traditional fixed-speed pumps, this system allows variable speed control, which means the pump can automatically adjust its operation according to water demand and sunlight availability.

Advanced Vector Control Technology

Modern solar pump inverters, such as the KV100A series (ranging from 0.75–22KW), feature high-performance vector control. This technology supports both sensorless vector control and closed-loop vector control, enabling precise motor speed adjustment, high dynamic response, and strong torque control. This ensures stable pump performance even under fluctuating solar power conditions.

Difference from Conventional Pumps

Traditional pumps usually operate at a fixed speed, consuming the same amount of energy regardless of actual water demand. By contrast, a solar pump inverter dynamically regulates motor speed, which not only saves energy but also prevents mechanical stress on the pump. The result is higher efficiency, lower wear and tear, and greater adaptability to real-world operating environments.

Why Is a Solar Pump Inverter Essential for Modern Irrigation and Water Supply?

Energy Efficiency and Cost Savings

One of the main reasons the solar pump inverter has become essential is its ability to significantly reduce energy consumption. By using renewable solar energy instead of grid power or diesel generators, water pumping systems achieve long-term cost savings. In addition, the inverter adjusts the pump speed according to actual demand, avoiding unnecessary power waste and ensuring optimal efficiency throughout the day.

Stable Water Supply in Varying Conditions

Water demand often fluctuates depending on crop growth stages, seasonal requirements, or livestock needs. A solar pump inverter provides real-time adjustment, delivering just the right amount of water without overloading the system. Even when sunlight intensity changes, advanced models like the KV90PV series (0.75–30KW) maintain stable performance, ensuring reliable water supply for irrigation, community distribution, or industrial use.

Intelligent Control and System Protection

Beyond basic power conversion, solar pump inverters also provide protection features such as overload prevention, dry-run detection, and automatic restart after voltage fluctuations. These functions reduce the risk of system failure, minimize downtime, and protect the investment in pumping equipment.

Adaptability Across Different Scales

From small-scale farms to large irrigation projects, there are suitable solar pump inverter models for every requirement. For instance:

KV100A-0.75–2.2KW is ideal for small farms and garden irrigation.

KV100A-7.5–15KW supports medium-scale irrigation or livestock water supply.

KV100A-18.5–22KW and KV90PV-22–30KW handle high-capacity pumping for industrial or community-level water systems.

This scalability makes solar pump inverters versatile solutions that can be customized to different projects and operational needs.

How Does a Solar Pump Inverter Improve System Efficiency and Equipment Lifespan?

Optimized Energy Use

A solar pump inverter ensures that the pump only runs at the speed required for actual water demand. This eliminates the wasteful full-speed operation common in conventional pumps. By regulating output based on sunlight conditions and water flow requirements, the inverter maximizes energy use while preventing overconsumption. The result is lower operating costs and improved sustainability.

Reduced Mechanical Stress

Constant high-speed operation often causes premature wear and tear on motors and pump components. With the solar pump inverter’s vector control technology, pumps can start smoothly, accelerate gradually, and adjust speed intelligently. This soft-start and controlled operation reduce sudden stress on bearings, shafts, and impellers, extending the equipment’s service life.

Protection Against Common Failures

Advanced models, such as the KV100A-4–5.5KW and KV90PV-7.5–11KW, come with built-in protection features. These include safeguards against overvoltage, undervoltage, overload, overheating, and dry running. By preventing damage before it happens, these inverters not only reduce maintenance frequency but also minimize costly downtime.

Long-Term Value and ROI

Investing in a solar pump inverter translates into long-term returns. Lower energy bills, fewer repair costs, and extended pump lifespan all contribute to higher overall efficiency. For large-scale irrigation or industrial water systems, this advantage becomes even more significant, as it ensures operational continuity and financial savings over many years.

Which Applications Benefit the Most from a Solar Pump Inverter?

Agricultural Irrigation

One of the largest beneficiaries of the solar pump inverter is agriculture. Crops require different water volumes depending on growth stages and seasonal factors. A solar pump inverter allows precise water delivery, adjusting pump operation to actual irrigation needs. For example, models such as the KV100A-7.5–15KW are suitable for medium farms, ensuring that crops receive consistent hydration without energy waste.

Livestock Watering

Livestock farms often operate in remote areas with limited or unstable power supply. A solar pump inverter ensures continuous water flow to troughs, reducing reliance on diesel generators. Compact units like the KV100A-0.75–2.2KW are ideal for small-scale livestock watering, while high-power models like the KV90PV-22–30KW can handle large herds or ranch operations.

Industrial and Community Water Supply

Beyond farming, industries and communities also benefit from solar-powered pumping solutions. Factories, food processing plants, and municipal water systems require reliable water distribution. By using solar pump inverters, these systems achieve both cost savings and operational stability. Models such as the KV100A-18.5–22KW provide strong performance for industrial-grade pumping applications.

Remote and Off-Grid Locations

In many rural or isolated regions, connecting to the power grid is expensive or impractical. A solar pump inverter offers a practical alternative, delivering water without dependency on external electricity sources. For community water projects, the KV90PV series (ranging from 0.75–30KW) offers scalable options to match the size of the population served.

Sustainable Development Initiatives

As governments and organizations promote renewable energy adoption, solar pump inverters play a direct role in achieving sustainability goals. By reducing fossil fuel use and carbon emissions, they contribute to both environmental protection and long-term economic benefits.

How to Select the Right Solar Pump Inverter Model for Your Needs?

Matching Power Requirements

When choosing a solar pump inverter, the first step is to evaluate the power demand of your water pumping system. Smaller farms or garden irrigation projects can operate efficiently with lower-power models such as the KV100A-0.75–2.2KW. For medium-scale irrigation or livestock operations, mid-range models like the KV100A-7.5–15KW are more appropriate. Large-scale or industrial applications often require higher-capacity units such as the KV100A-18.5–22KW or KV90PV-22–30KW.

Considering Pump Type and Application

Different pumps, including submersible, centrifugal, and surface pumps, have specific requirements. Selecting the right solar pump inverter ensures optimal compatibility. For instance, the KV90PV series offers wide adaptability for various pump types, making it a reliable choice for projects that involve mixed systems.

Evaluating Environmental Conditions

Harsh environments, including areas with fluctuating sunlight or unstable grid backup, demand robust inverter features. High-performance vector control and built-in protection systems are crucial to maintain stability and extend the lifespan of pumps. In this case, advanced models like the KV100A-4–5.5KW or KV90PV-7.5–11KW can provide a balance between efficiency and durability.

Planning for Scalability and Long-Term Use

For organizations aiming at long-term development, scalability is an important factor. Investing in models that can support future expansion avoids unnecessary replacement costs. The KV series offers options from small-scale to large-capacity systems, ensuring flexibility as water demands grow.

LCGK Solar Pump Inverter Model Comparison

| Model | Power Range | Control Features | Suitable Applications |

| KV100A-0.75–2.2KW | 0.75–2.2KW | High-performance vector control (sensorless & closed-loop) | Small farms, gardens, livestock watering |

| KV100A-4–5.5KW | 4–5.5KW | Stable torque, strong dynamic response | Medium irrigation, small community supply |

| KV100A-7.5–15KW | 7.5–15KW | Precise motor adjustment, overload protection | Medium-scale irrigation & livestock systems |

| KV100A-18.5–22KW | 18.5–22KW | Industrial-grade control, robust protection features | Large farms, industrial water systems |

| KV90PV-0.75–2.25KW | 0.75–2.25KW | Solar-optimized vector control, energy efficiency | Household & small-scale irrigation |

| KV90PV-4–5.5KW | 4–5.5KW | High adaptability to solar fluctuations | Medium farms & rural communities |

| KV90PV-7.5–11KW | 7.5–11KW | Strong load capacity, multiple pump compatibility | Livestock, village water projects |

| KV90PV-15–18KW | 15–18KW | Advanced vector control with reliable torque output | Large irrigation projects |

| KV90PV-22–30KW | 22–30KW | High-capacity, industrial-grade inverter | Industrial plants & community water supply |

Conclusion

The solar pump inverter is more than just a power converter—it is a complete solution that combines efficiency, reliability, and sustainability. By selecting the right model based on power needs, pump type, and environmental conditions, businesses and organizations can achieve long-term cost savings and stable water supply.

For dependable performance across a wide range of applications, the LCGK KV100A and KV90PV series stand out as proven choices, offering advanced vector control, robust protection features, and scalable solutions designed to meet the challenges of modern irrigation and water supply.