Introduction

In today’s agricultural and industrial sectors, water management has become one of the most critical factors influencing productivity, efficiency, and sustainability. Traditional pumping systems, often powered by diesel engines or fixed-speed electric motors, are increasingly showing their limitations. High fuel consumption, rising operational costs, frequent maintenance needs, and unstable power supply in remote regions have created significant barriers for long-term development.

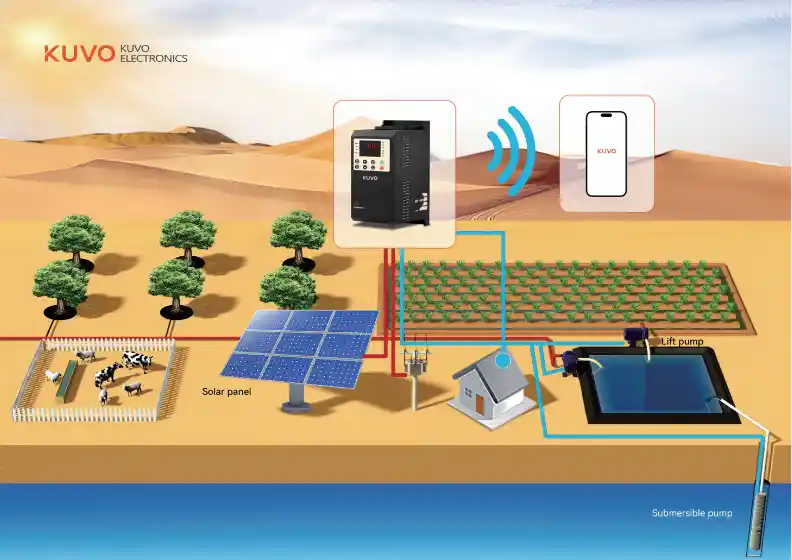

This is where the solar pump inverter has emerged as a transformative solution. By combining solar energy with advanced variable frequency drive (VFD) technology, it ensures stable water delivery while optimizing energy use. Unlike conventional pumps that operate at constant speeds regardless of demand, solar pump inverters intelligently adjust pump speed and water flow based on real-time requirements and solar input. This dynamic control not only reduces energy waste but also extends equipment lifespan and improves overall system reliability.

As businesses and communities search for smarter, cost-effective, and environmentally sustainable alternatives, the adoption of solar pump inverters is accelerating worldwide. From small-scale farms and greenhouses to large irrigation projects and industrial water supply systems, this technology provides a practical pathway to efficiency and long-term value.

What Challenges Do Traditional Irrigation and Pumping Systems Face?

High Energy Consumption and Rising Costs

Conventional irrigation pumps, whether powered by diesel engines or fixed-speed electric motors, often consume more energy than required. Since they cannot automatically adjust to fluctuating water demand, they continue running at full capacity even during periods of low usage. This results in unnecessary energy waste, higher fuel or electricity bills, and increased pressure on farmers and industries trying to optimize operating costs.

Limited Adaptability in Remote and Off-Grid Areas

Many agricultural projects and industrial facilities are located in areas where access to stable grid electricity is either limited or unavailable. Diesel-powered pumps, while common, bring challenges such as frequent fuel transportation, price fluctuations, and environmental concerns. This dependency restricts scalability and makes long-term water management less reliable in remote regions.

Frequent Maintenance and Reduced Equipment Lifespan

Fixed-speed pumping systems often suffer from mechanical stress because of continuous operation at maximum load. Over time, this leads to frequent breakdowns, higher repair costs, and shorter equipment lifespan. For agricultural users who depend on pumps during peak seasons, unexpected downtime can cause significant losses in crop yield and productivity.

Environmental Concerns and Sustainability Issues

Traditional pumping solutions rely heavily on fossil fuels, contributing to greenhouse gas emissions and environmental degradation. With growing emphasis on sustainability and regulatory compliance, businesses and farms face increasing pressure to reduce their carbon footprint. Conventional pumps simply cannot align with the environmental goals and long-term strategies many organizations are pursuing today.

How Does a Solar Pump Inverter Improve Energy Efficiency and Water Management?

Smart Integration of Solar Power and Variable Frequency Drive (VFD)

The solar pump inverter combines renewable solar energy with VFD technology, creating a more intelligent pumping system. Instead of operating at a constant speed, the inverter regulates motor frequency and voltage, ensuring that water output precisely matches actual demand. This prevents energy waste while making full use of available solar power throughout the day.

Dynamic Adjustment to Real-Time Water Needs

One of the core advantages of solar pump inverters is their ability to adjust water flow dynamically. During peak sunlight hours, the inverter increases pump speed to maximize efficiency. When solar input decreases, it scales down operations to maintain consistent performance. This adaptability not only stabilizes water supply but also reduces the risk of system overload.

Reduced Operational Costs and Energy Savings

By replacing diesel-powered or grid-dependent pumps, solar pump inverters significantly lower ongoing operational expenses. Fuel costs, electricity bills, and transport-related expenses are minimized, providing a fast return on investment. For example, when using models such as KV100A-7.5-15KW or KV90PV-7.5KW-11KW, users can benefit from stable water delivery with lower long-term energy costs.

Extending Pump Lifespan and Improving Reliability

Traditional pumps often operate at maximum load, causing mechanical stress and frequent failures. In contrast, solar pump inverters distribute workload more evenly, reducing wear and tear. This extends equipment lifespan, lowers maintenance requirements, and ensures higher reliability, especially during critical irrigation or industrial production periods.

Supporting Sustainable Development Goals

By utilizing renewable solar energy, solar pump inverters contribute directly to sustainability initiatives. They reduce dependence on fossil fuels, cut greenhouse gas emissions, and support compliance with environmental regulations. For organizations seeking both efficiency and eco-friendly practices, this technology represents a balanced solution.

What Are the Key Features of Modern Solar Pump Inverters?

High-Performance Vector Control

Modern solar pump inverters are designed with advanced vector control technology, which supports both sensor-free vector control and closed-loop vector control. This ensures high dynamic response and precise motor operation, allowing pumps to run smoothly even under variable water demands. For instance, models like KV100A-18.5-22KW and KV100A-7.5-15KW provide stable output while maintaining efficiency across different conditions.

Wide Power Range for Flexible Applications

The LCGK product lineup offers a broad range of capacities to suit diverse project scales:

Small-scale systems such as KV100A-0.75-2.2KW and KV90PV-0.75-2.25KW are ideal for greenhouses, gardens, and small farms.

Mid-range models like KV100A-4-5.5KW and KV90PV-7.5KW-11KW fit medium farms, orchards, and small industrial facilities.

High-capacity units including KV90PV-22-30KW and KV100A-18.5-22KW are designed for large-scale irrigation projects, community water supply, or industrial water systems.

This scalability ensures that businesses can select the most appropriate inverter for their needs without overinvesting in oversized equipment.

Stable Operation in Variable Conditions

Solar pump inverters are engineered to adapt to fluctuating sunlight and water demand. The built-in control algorithms prevent pump stalling and maintain stable water flow even during cloudy weather or partial shading. This makes them highly reliable for both agricultural and industrial environments where water supply consistency is critical.

Cost Efficiency and Long-Term Value

Unlike conventional diesel pumps that incur continuous fuel costs, solar pump inverters operate directly from renewable energy. Combined with reduced maintenance requirements, they offer long-term savings that outweigh the initial investment. Businesses using KV90PV-15-18KW or KV90PV-22-30KW models, for example, can benefit from significant cost reductions over time.

Easy Integration and User-Friendly Design

Modern units are designed for simple installation and integration with existing pumping systems. Features such as automatic water-level control, dry-run protection, and overload protection reduce system risk and improve usability. This ensures that operators can manage systems efficiently without requiring extensive technical expertise.

Why Is a Solar Pump Inverter Suitable for Agricultural and Industrial Applications?

Precision Irrigation for Agriculture

In farming, water management directly impacts crop yield and resource efficiency. A solar pump inverter enables farmers to match water flow with crop needs in real time, ensuring that fields receive the right amount of water without waste. Models such as KV100A-4-5.5KW are particularly effective for small and medium-sized farms where water distribution must be both precise and consistent.

Reliable Water Supply for Large-Scale Farming

For larger agricultural projects, stability and capacity are critical. High-power inverters like KV90PV-22-30KW or KV100A-18.5-22KW provide the energy efficiency and pumping strength needed to support extensive irrigation systems. These systems can operate seamlessly during peak seasons, minimizing downtime and ensuring reliable water supply across wide fields.

Industrial Water Management and Production Processes

Beyond agriculture, industries also rely on consistent water supply for production lines, cooling systems, and facility operations. A solar pump inverter ensures uninterrupted performance by regulating pump speed and adapting to demand changes. Mid-range models such as KV90PV-7.5-11KW are ideal for manufacturing plants where reliability and operational cost savings are top priorities.

Long-Term Cost Reduction and ROI

Both agricultural and industrial users benefit from significant cost reductions when switching from diesel-powered pumps to solar-driven inverters. By eliminating fuel costs, reducing maintenance, and extending equipment lifespan, organizations achieve faster return on investment. Over time, this improves financial stability and supports long-term sustainability goals.

Supporting Environmental Responsibility

Sustainability is no longer optional—it is a necessity. Solar pump inverters reduce reliance on fossil fuels, minimize greenhouse gas emissions, and align with international environmental standards. For companies and farms aiming to demonstrate eco-friendly practices, adopting models like KV100A-7.5-15KW or KV90PV-15-18KW provides both operational and reputational advantages.

How to Select the Right Solar Pump Inverter for Different Project Scales?

Small-Scale Farms, Gardens, and Greenhouses

For smaller agricultural plots or greenhouse environments, energy requirements are relatively low, but precise water delivery remains essential. Compact models such as KV100A-0.75-2.2KW or KV90PV-0.75-2.25KW are designed to meet these needs. They ensure stable performance, protect against dry-run conditions, and deliver reliable operation at an affordable investment level.

Medium-Sized Agricultural Projects and Industrial Facilities

When water demand increases, choosing mid-range solar pump inverters becomes crucial. Models like KV100A-4-5.5KW, KV100A-7.5-15KW, or KV90PV-7.5-11KW balance power and efficiency, making them suitable for orchards, livestock farms, and medium-scale industrial plants. These units provide flexibility in adjusting pump speeds while keeping operational costs under control.

Large-Scale Irrigation Systems and Community Water Supply

For extensive farmland, industrial complexes, or community water projects, higher-capacity inverters are required. Options such as KV100A-18.5-22KW, KV90PV-15-18KW, and KV90PV-22-30KW deliver robust performance, ensuring that large pumping systems remain efficient and reliable even under heavy workloads. Their advanced vector control and durability make them ideal for demanding, continuous-use environments.

Factors to Consider When Choosing

Water Source and Depth: Deeper wells require higher-capacity inverters to ensure sufficient pumping power.

Daily Water Demand: Match inverter output with irrigation schedules or industrial requirements.

Budget and ROI: Smaller units minimize upfront cost, while larger models deliver better long-term savings in high-demand projects.

Environmental Conditions: Ensure that the selected inverter is equipped with protections such as overload, overheating, and dry-run safeguards.

By aligning project scale with the appropriate model, businesses and farms can maximize system efficiency, reduce operational risks, and achieve long-term sustainability.

Conclusion

The transition from traditional pumping systems to solar pump inverters marks a significant step toward energy efficiency, reliability, and sustainability. By integrating solar energy with advanced variable frequency drive technology, these systems address long-standing challenges such as high operational costs, limited adaptability in off-grid areas, and excessive equipment wear.

From small-scale farms and greenhouses to large industrial facilities and community water supply projects, solar pump inverters provide tailored solutions that meet diverse requirements. Small-capacity models ensure affordability and precise control, mid-range units deliver balance for expanding operations, and high-power inverters support the most demanding irrigation and industrial systems. Regardless of the application, the benefits are clear: reduced energy consumption, extended equipment lifespan, and long-term financial savings.

As global industries and agricultural sectors continue to prioritize sustainability and operational efficiency, the adoption of solar pump inverters will only accelerate. Choosing the right model ensures not only stable water management but also alignment with future-focused environmental goals.

For businesses and projects seeking proven solutions, LCGK offers a complete lineup of reliable options, including the KV100A series and KV90PV series, designed to deliver high performance across every scale of application. With advanced vector control, robust protection features, and adaptability to real-world challenges, LCGK VFD solar pump inverters stand out as a dependable partner for sustainable growth.